As electronic products become smaller, more complex, and more performance-driven, design decisions made early in development have an outsized impact on cost, reliability, and speed to market. Flex circuit manufacturing has become a critical enabler for modern electronics, enabling engineers to overcome space constraints, mitigate mechanical risks, and simplify assembly.

When flexible printed circuits (FPCs) and rigid-flex designs are considered from the start, teams can avoid costly redesigns, streamline production, and deliver higher-quality products—especially in high-reliability industries such as medical, aerospace, defense, and semiconductor equipment.

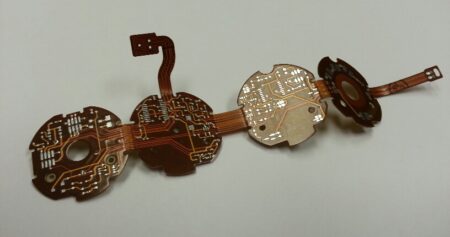

The above image shows a 4 layer flex board created by Green Circuits.

Flex circuit manufacturing involves producing printed circuits on flexible base materials that can bend, fold, or conform to the physical shape of a product while maintaining electrical integrity.

Unlike traditional rigid PCBs, flex circuits allow designers to route signals through tight spaces, eliminate bulky wire harnesses, and reduce the number of interconnects within a system. These advantages are most effective when flex circuits are incorporated early in the design process, enabling better decisions around layer stackups, materials, bend areas, and overall manufacturability.

From a design-for-manufacturability (DFM) perspective, early collaboration with an experienced flex circuit manufacturer helps ensure the design is both electrically sound and production-ready, minimizing delays later in the development process.

Flex circuits are widely used in applications where reliability is critical and operating conditions are harsh. By reducing connectors, solder joints, and mechanical interfaces, flex circuits significantly lower the number of potential failure points in an electronic system.

Their lower mass and inherent ductility improve resistance to shock and vibration, while modern flex materials are engineered to perform reliably in high-temperature, high-motion, and chemically aggressive environments. The thin profile of flex circuits also promotes better airflow and heat dissipation, helping electronics maintain stable performance over time.

These characteristics make flex circuit manufacturing especially valuable in mission-critical electronics where long-term durability and consistent performance are required.

One of the most practical benefits of flex circuit manufacturing is its impact on assembly efficiency and overall product design.

By replacing wire harnesses and manual routing, flex circuits:

At the same time, flex circuits enable significant reductions in size and weight—often providing up to 60% space savings compared to rigid boards and cables. This added design freedom allows engineers to create more compact, lightweight, and visually refined products without sacrificing functionality or reliability.

While the per-unit cost of a flex circuit may be higher than a rigid PCB, the total system cost is often lower.

Flex circuit manufacturing reduces overall cost by:

When evaluated across the full product lifecycle, flex circuits frequently deliver a lower total cost of ownership—particularly in complex or high-reliability applications.

Successful flex circuit design requires careful attention to both electrical and mechanical factors.

Key considerations include bend radius requirements, expected flex cycles, material selection for thermal and environmental performance, layer stackups, and assembly constraints. Addressing these factors early—and validating them with a qualified manufacturing partner—helps prevent costly redesigns and ensures first-pass success.

Green Circuits specializes in flex and rigid-flex circuit manufacturing, supporting customers from early prototypes through full-scale production. Our team brings deep PCB expertise and a consultative approach to every project, helping customers improve design viability, accelerate development timelines, and meet stringent quality and compliance requirements.

We support high-reliability industries including medical devices, aerospace and defense, semiconductor equipment, and industrial systems—delivering solutions engineered for speed, precision, and performance.

Designing products with flex circuits in mind is no longer optional for advanced electronics—it’s a competitive advantage. With the right design strategy and manufacturing partner, flex circuit manufacturing enables improved reliability, better performance, and more efficient production.

To learn how Green Circuits can support your next flex or rigid-flex project, request a quote and hear from a team member within 24 hours.