PCB Assembly Capabilities and Equipment

Green Circuits is a full-service electronics and design company specializing in Quick-turn, High-Mix, High-Complexity, Flex, and Rigid Circuit Board Assemblies for Quick-turn Prototypes, NPI and Low to Medium Volume Production

Green Circuits Manufacturing Facility

Located in San Jose, California, Green Circuits operates a state-of-the-art 60,000-square-foot manufacturing facility featuring five advanced SMT lines equipped with 20 top-tier Juki machines, ensuring high-quality, rapid, and quick turnaround.

Our Advantages:

- Dedicated Program Manager and Buyers

- Fast and Responsive Customer Support

- Expedited Quoting Process

- Quick-Turn Prototyping

Green Circuits delivers speed, quality, and unparalleled customer service.

5 Surface Mount Technology (SMT) Placement Lines

The manufacturing facility is designed with 5 independent SMT production lines to concurrently handle a wide range and scope of projects. The production line configuration was specifically designed for rapid configuration and scalability from small prototype to full-scale specialty production.

Production Line Equipment and Capabilities:

- Surface Mount Screen Printers by DEK & Juki

- Juki SMT for Pick and Place Machines

- Large Number of Feeders for High Production Through-Put

- 5 BTU & Heller 10-Zone Convection Reflow Ovens

- 3 Selective Solder Machines for Through-Hole Components

- Multi-Inspection Checkpoints

- QC Inspection

- Automated Optical Inspection (AOI)

- XRay Machines

- Water and Chemical Wash Machines

- Electrical Flying Probe Testing

- PCB Assembly Final Testing

- Rework BGA and Reballing

- System Box Build Assembly and Integration Services

5 Production Lines: Equipment and Capabilities

Surface Mount Screen Printers by Juke and DEK

Each SMT line is comprised of Juki or DEK solder paste screen printer to precisely screen solder paste on the stencil and accurately apply the solder paste to each PCB.

This process includes an automated inline 3D inspection system by VI Technologies to assure each PCB has accurately applied solder paste volume before proceeding to the next step in the SMT line.

Surface Mount Technology (SMT)

Each SMT production line has a minimum of 5 SMT Juki pick-and-place machines designed to precisely place electronic components onto printed circuit boards (PCBs) during the assembly process.

Juki SMT pick-and-place are known for their high accuracy and precision. They can place a wide range of components, from .01005 resistors and capacitors to large integrated circuits down to .025mm on designated spots on the PCB Assemblies with pinpoint precision.

Green Circuits has a large number of pre-configured feeders and trolleys allowing quick change-over which allow for a large number of PCB Assemblies and quick-turns per day.

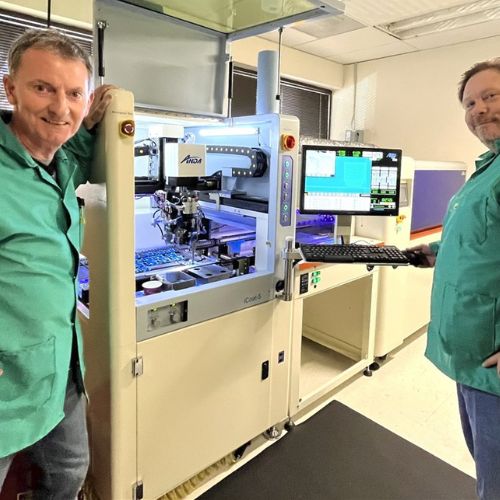

Conformal Coating Machine

Green Circuits has an in-house Anda Technologies, iCoat-5 is a high-speed precision selective conformal coating machine that’s designed to deliver the highest quality in accuracy and precision for automated batch or in-line conformal coating processes.

Full range of material availability

- Acrylic

- Urethane

- Silicone

- Epoxies

- Parylene (outside service)

- Running accuracy of ± 0.02 mm (20 µm) (± 0.0007ʺ)

- Five axes of movement (X,Y,Z,U rotation) and 35° tilt

- Single head turret design supporting up to three selective conformal coating valves that can be arranged in a variety of different nozzle configurations

5 Heller 10-Zone Reflow Ovens

Each SMT Line has a 10-zone reflow oven with nitrogen reflow capability. Green Circuits process engineer will generate a specific oven profile for each SMT board with a data pack mole. The data pack mole will ensure that the PCBAs will reflow and cool down at the exact temperature for its application.

Nitrogen reflow will be used on complex boards with small SMT parts or thick copper mass. With nitrogen filling the reflow oven, it gives the solder paste and board a longer soldering zone. Green Circuits has found great success with nitrogen on 0201 or smaller capacitors and resistors, microBGAs, and thick PCBs with heavy copper.

Low-Volume Through-Hole Component Assembly

In-House Hand Soldiering

For projects with low-volume through-hole PCBA components, Green Circuits provides hand soldering by highly skilled, experienced technicians.

High-Volume Through-Hole Component Assembly

In-House Selective Solder Machines

Green Circuits has 3 Juki 460 Selective Solder Machines for high-volume, through-hole PCBA Components. This offers precision and selective soldering of PCB’s for specific points or components using programmable solder profiles for high precision, flexibility and reduced thermal stress.

- Three – Juki Cube 460 Selective Solder Systems

- Press Fit Tool Arbor Press S-3550

- CD-LFC510 Wave Solder

Quality Control Inspection

Every PCBA is hand inspected!

Every PCBA must go through our First Article Inspection (FAI) station where an IPC certified inspector manually and thoroughly examines each board for the accurate placement of components and solder quality to assure zero solder defects.

The technician uses customer drawings, bill of materials and specifications to assure accuracy as the 1st stage of Green Circuits Quality Control Program.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) serves as a critical step in the Green Circuits assembly process, ensuring the quality and precision in the PCBA assembly line. This uses high-resolution cameras to thoroughly scan the surface of PCBAs, identifying any defects such as soldering errors, missing components, or misalignments.

The AOI process is vital to Green Circuits' quality inspection capabilities by confirming that the placement and soldering of each component meet strict quality standards, thereby greatly reducing the likelihood of PCBA failures.

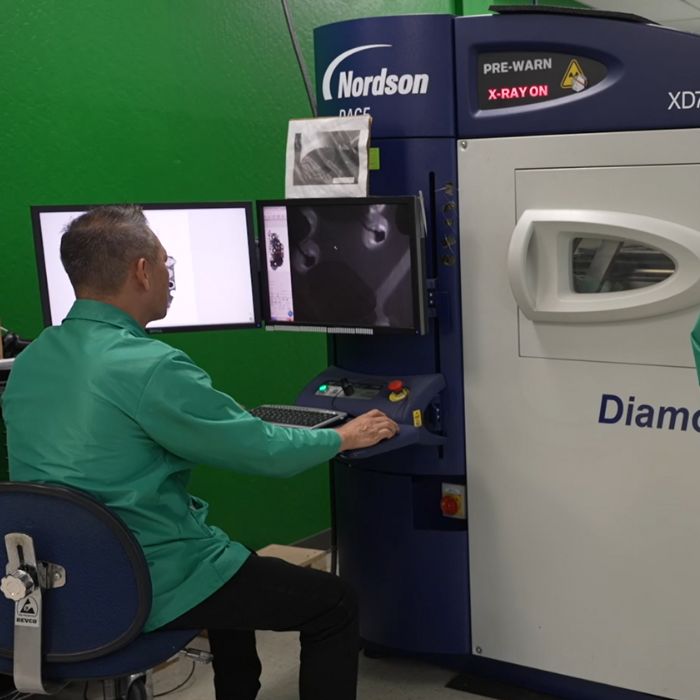

XRay Inspection Machine

Green Circuits production line includes Nordson DAGE XD7600NT Ruby X-Ray Inspection Machines as a critical role in the quality assurance process. Skilled inspectors can look deep into the heart of the circuit board to spot soldering errors, misalignments, and hidden issues with unmatched clarity.

This equipment ensures our PCBAs not only meet but exceed quality and reliability standards, crucial for complex electronic devices. Its role in our lead-free soldering process is pivotal, safeguarding every solder joint and component. By integrating the XD7600NT Ruby, Green Circuits continues to lead the pack in producing flawless PCBAs, ready for any high-stakes application.

Wash Stations

Green Circuits’ production lines includes inline cleaning systems use specially formulated solutions to remove flux residues, contaminants, and soldering byproducts, ensuring each circuit board is pristine before moving on to the next phase of assembly.

This not only enhances the electrical functionality and longevity of the PCBA but also prevents potential issues that could arise from impurities. By incorporating advanced wash machines into our production line, we guarantee a level of cleanliness that meets the highest industry standards, contributing significantly to the overall quality and reliability of our electronic devices. This commitment to excellence through cleanliness is a testament to our dedication to delivering superior products every time.

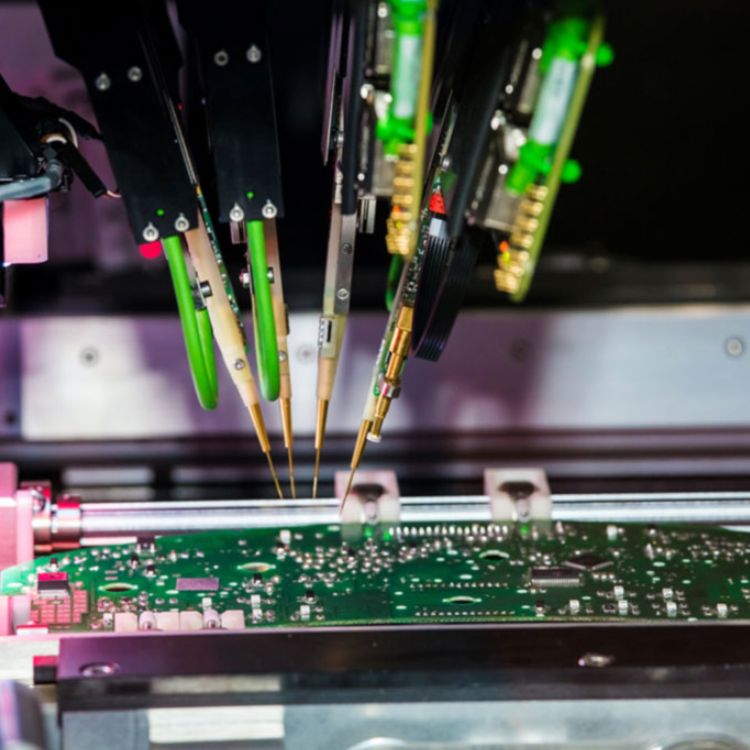

Electrical Testing

Functional, Burn-In and Flying Probe

Green Circuits has 3 (single and double sided) flying probe machines for precise electrical testing. These flying probe testing machine are a crucial tool in the PCBA assembly, designed to test boards' electrical functionality efficiently without the need for custom fixtures.

Utilizing movable probes, it swiftly checks connectivity, identifies defects, and assesses component values directly on the PCBA. Its flexibility makes it ideal for prototypes and low-volume productions, offering a cost-effective solution for ensuring quality.

With the capability to access tight spots and perform detailed inspections, flying probe testers are essential for verifying the precision and reliability of PCBAs, especially in complex designs, ensuring each board meets high standards before advancing in the production process or reaching customers.

Final Quality Control

IPC Trained and Certified Inspectors

Before shipment to the customer, each completed PCBA board goes through a final inspected by IPC trained and certified inspectors using the customers drawings to ensure the product is built to the specifications, zero-defects and cleanliness.

BGA Rework

Today’s circuit boards are more complex than ever and the need for circuit board repair and rework is a given. BGA rework is one of the most difficult procedures at assembly facilities. Doing it right depends on the skills and knowledge of the rework technician, along with having the right equipment.

With 30+ years of experience in printed circuit board fabrication, assembly and rework, and state-of-the art equipment, Green Circuits’ rework technicians use the proper materials and methods to troubleshoot, diagnose, and rework a wide variety of issues.

- Component Removal and Replacement

- Component Salvage

- Circuit Design Changes

- Circuit Pattern Design Changes

- Optical Verification Services

- Pad/Trace Repair

- Solder Mask Repair

- X-ray Inspection

System/Box Build

Let Green Circuits build you a finished, functional unit!

For customers that require a complete assembly of the product, Green Circuits offers custom built stations to assemble components from sub-assembly installation, cable assemblies, wiring harness, PCB’s insertion, software loading, product configuration, functional level testing, packaging & labeling and order fulfillment.