As circuits get smaller and more compact, they become more susceptible to electrostatic discharge (ESD) and damage. According to the ESD Association, 25% of all electronics that are ‘damaged for unknown reasons’ can be attributed to ESD, with estimated ESD damages costing the electronics industry $5 billion a year.

Disregard to ESD protection during the electronic assembly process can result in permanent circuitry damage, failure and increased production costs; as well as a reduction or loss in customer confidence toward your product’s reliability.

To ensure maximum ESD protection for your electronic assemblies and prevent ESD damage, Green Circuits’ experts recommend implementing 3 levels of protection for electronic circuits:

Facility ESD Protection Zones: Electrostatic Discharge Protected Areas (EPAs) safeguard ESD-sensitive electronics from common sources of electrostatic discharge, by grounding conductive materials and workers in ESD-susceptible production areas, that include:

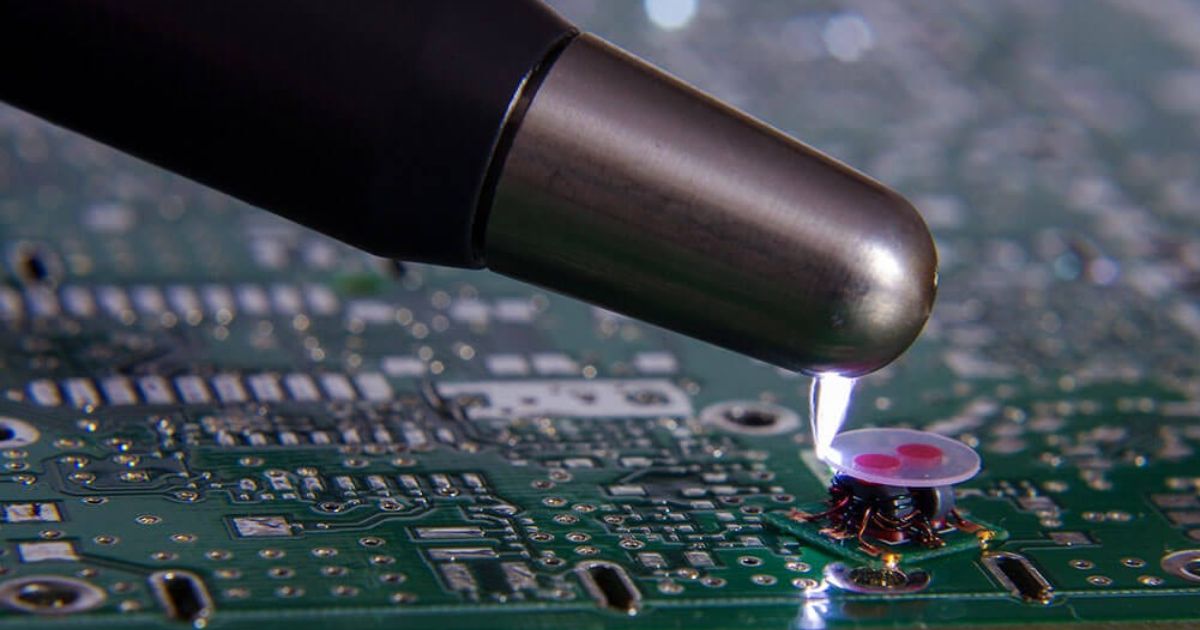

Built-In ESD Protection for Circuits: Built-in ESD protection reduces the risk of total circuit failure or latent damage when assemblies are most vulnerable, such as during electronic assembly. Best practices for built-in ESD protection include:

ESD-Controlled Circuit Board Storage and Transportation: The risk of ESD is not eliminated after production, measures must also be taken to protect boards during storage and transportation, too. The most commonly-used solutions to store and transport electronic circuits is an ESD bag. ESD bags are anti-static bags, modeled on the Faraday Cage principle, and made with fine layers of metal to seal the contents from external charges.

ESD control is an integral part of Green Circuits’ electronic design and assembly services offering. Each production-related task is completed in Green Circuits’ 62,000-square foot, ESD-controlled facility and is performed by Green Circuits’ experienced electronics assembly team. This team of experts has been instrumental in the development of groundbreaking products for an array of industries and organizations, such as NASA and Freedom Innovation, that rely on Green Circuits’ precision and reliable output.

Additional resources and standards to reduce electrostatic are available from the American National Standards Institute (ANSI) and International Electrotechnical Commission (IEC).

For more information, visit www.greencircuits.com.