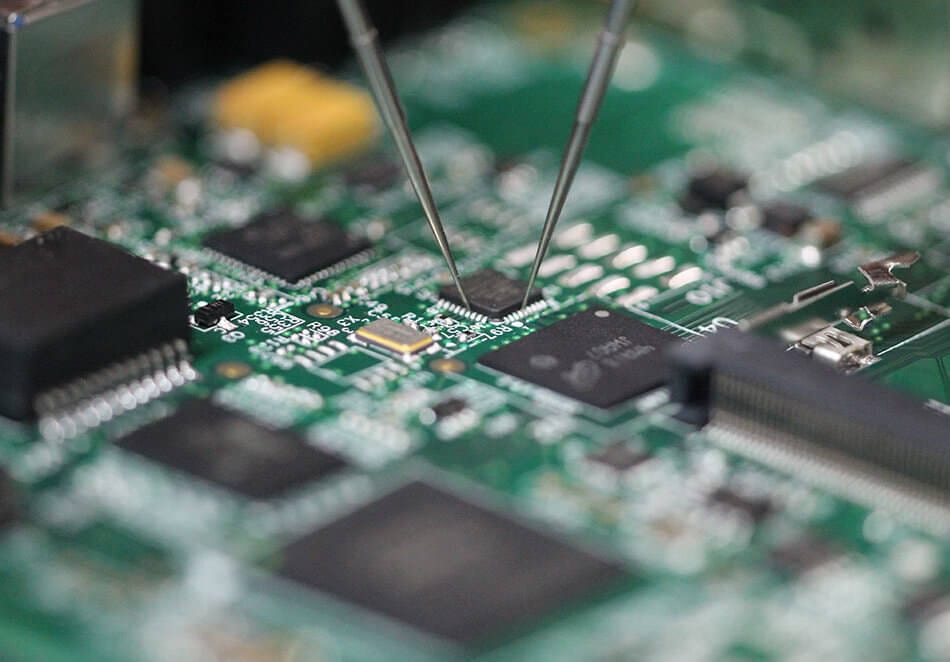

Full Electronic Enclosure Assembly Considerations

Tips to Design Waterproof Enclosures for Your High Performance Products

Waterproof electronic enclosures are a gold standard in virtually every industry. From smartphones and wearables to underwater cameras—customers are extremely concerned about the waterproof rating as it affects both performance and durability. Having assembled circuit boards for a wide range of applications, we highly recommend getting your enclosure design right the first time. This will avoid the risk of ruining an expensive prototype and delaying your product launch.

3 Important Considerations for Full Electronic Enclosure Assembly

- Waterproof ratings – Engineers are often confused about what rating to look for in a waterproof enclosure. Typical “waterproof” IP ratings are:

- IP65 – Protect against water jets projected from a 6.3mm nozzle

- IP66 – Protection against powerful water jets from a 12.5 mm nozzle

- IP67 – Protection against immersion/submersion to a depth of 1m

Our PCB assembly specialists suggest considering the environment in which your product will be used and then testing electronic enclosures for both static and water jet pressure to be absolutely safe.

- Choosing a seal that works – Seals and gaskets create a barrier between housing and enclosure. Being a critical factor in water resistance, it is important to select one that will suit the product environment. Performance requirements such as water spray or submersion determine the sealing material, hardness and design elements. Custom designs and the right material can help achieve the desired compression and thickness while solving any shape-related problems.

- Prototype assembly and testing recommendations: Select a lower resolution material to check aesthetics and test the fit and function of your prototypes. This can help reduce cost. For the waterproofing test, you will have to use high resolution materials to ensure proper sealing. For high pressure sealing, we recommend CNC machining. This will guarantee surface control quality prior to testing the prototype for water resistance.

From design assistance to warehousing, shipping and inventory control, we offer complete solutions, including a layout review and manufacturing feasibility assessment of your electronic box builds and enclosure designs to reduce production time and costs.

Request a quote for electronic enclosures or call us today at (408) 526-1700 to speak with a representative about reducing the production time and costs of your upcoming project.