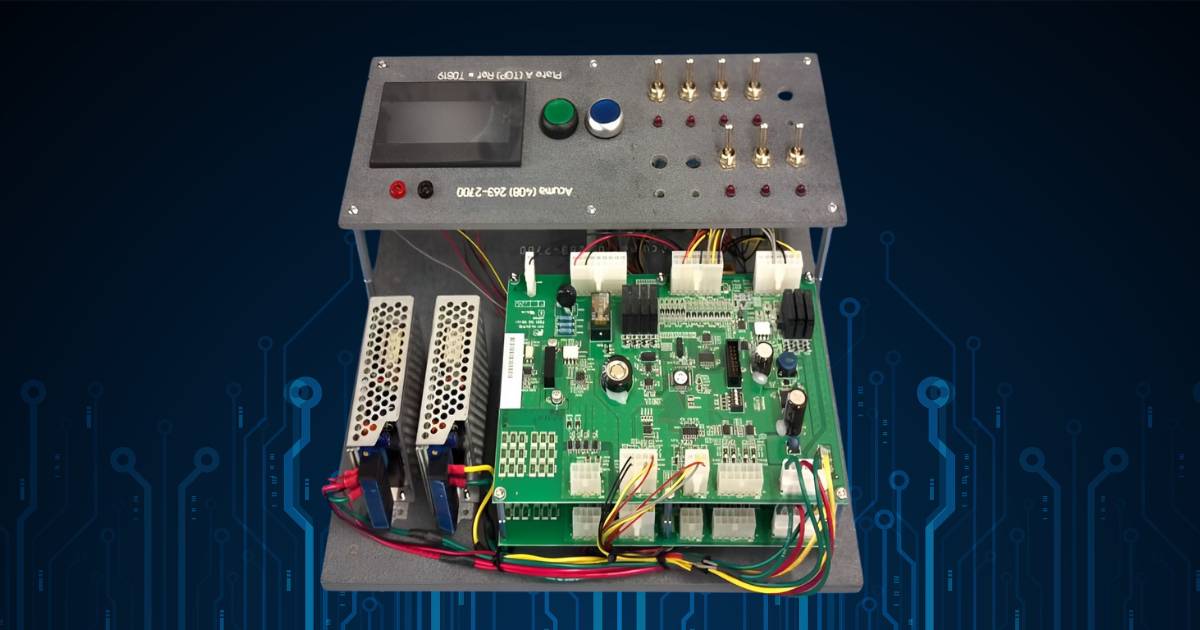

Box builds are quite different from straightforward printed circuit board manufacturing.

The process of a box build often begins with inserting a PCB into a specially constructed enclosure. The next step – connecting the framed, printed circuit board to a sub-assembly – can be simple, or involve linking to complex electro-mechanical assemblies that border on machines.

However, each successful box build project begins with expert planning.

Collaboration is Key on Box Build Projects

Green Circuits’ reputation is based on our ability to give clients what they want, when they want, but ours is not a one-sided approach. We rely on clients to provide us with the information we require to create a fully functioning box build that meets their specifications.

The first step in any box build project is an in-depth discussion. The Green Circuits engineer in charge of the project needs to understand some basic concepts, such as your goals for the final product and a timeline for completion.

In addition, we typically ask our clients to provide:

- A basic design. Green Circuits has completed box builds drawn from incredibly rough sketches, but even our talented engineers benefit from designs that include basic dimensions and convey an idea of overall size and weight. CAD models in 3-D, even if they are extensively revised later in the process, are helpful at the beginning of a project. A working knowledge of the dimensions of a box build is also helpful in calculating packaging and shipping logistics.

- A list of materials. Green Circuits handles the acquisition of most materials for every box build project. Clients sometimes prefer to provide basic materials. An itemized list of all components – such as pneumatics, switches, encoders and timers – and their prices needs compiling and, if necessary, to be updated throughout the project. Spelling out who is responsible for acquiring materials eliminates confusion and keeps the process on track.

- Testing requirements. Our engineers are happy to advise you on which tests should be performed before the box build hits the market. In many instances, clients who understand how they want their products to function are better off conducting tests themselves and allowing Green Circuits to make adjustments, if needed.

Call Us When Your Box Build Project Has to Be Done Right

Green Circuits’ precision box builds serve a variety of industries, including aerospace, telecommunications, medical device and semiconductor manufacturing. We’re

ISO-9000 certified, with the highest production standards in the electronics industry.

Discuss the planning of your successful box build project with a Green Circuits representative.

Request an online quote today, or call 408-526-1700.

For more information, visit www.greencircuits.com.