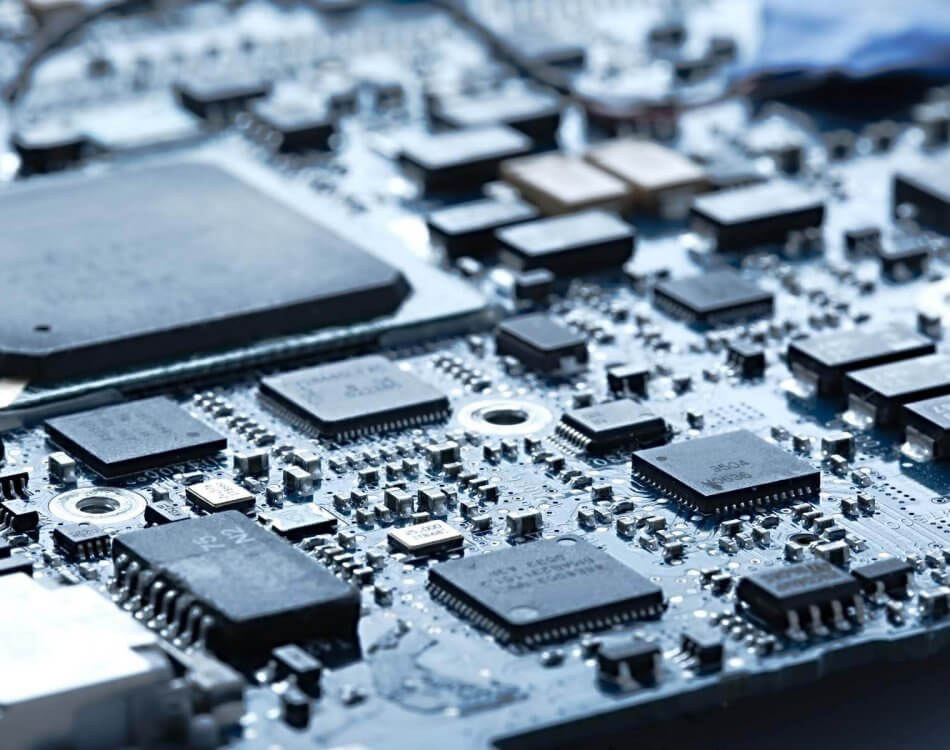

PCB Material Options – Why They Matter?

The success of your Printed Circuit Board is dependent on its design, assembly, and materials. But with an array of PCB material options to consider; how do you select the most effective material for your design?

Prior to making a material selection, it is important to consider factors like user interaction, thermal exposure (internally and externally), environmental conditions, component location, and design. Evaluating these variables will allow you to choose the right materials to support the manufacturability, longevity, and performance of your product.

Before starting your project, we strongly advise consulting with your PCB service provider regarding your PCB material options. Request A Quote or Contact Us to get started!

Circuit Board Materials

Standard Rigid FR4

This cost-efficient board is easy for designers and fabricators to work with because of its electrical and mechanical characteristics. The composition of the board results in predictable and consistent fabrication. This board type is ideal for automotive and wireless communication applications.

Other applications:

- MCM-Ls

- Direct chip attachment

- High-volume fine line multi-layer

- PCMCIAs

Flex and Rigid-Flex

Flex-circuits have become increasingly popular and support the reduction of an application’s size and weight due to their flexibility, and are ideal for high temperature and high-density applications. This board type is ideal for medical and mobile consumer electronic applications Commonly manufactured using “Kapton”, a polyimide film-based material developed by Dupont Corporation, it is resistant to heat, has dimensional stability and a low dielectric constant of 3.6.

There are three variants of the Kapton material:

- Pyralux LF (Acrylic Base Adhesive-not Flame Retardant)

- Pyralux FR (Acrylic Base Adhesive-Flame Retardant)

- Pyralux AP (Adhesiveless-for more demanding high-performance applications)

Green Circuits Expert PCBA Manufacturing & Services

- Quote in 4 hours or less!

- Expert Service & Production Teams

- Turnkey Assembly in 1-3 Day Turn

- Accelerated Time to Market

- Flexible Production & Scalability

- Advanced Production Equipment

- Proven Quality Management System

- 24/7 Services & Support

RF/Microwave/High Speed

RF/Microwave/High Speed are commonly used and cost-effective laminates for boards due to their dielectric and thermal conductivity characteristics. These board types are ideal for technologies with a microprocessor and for wireless communication applications.

Rogers Corporation

- 5870/5880 series

- 3003/3006/3010 series

- 6002/6006 series

- 4003/4350 series

- TMM4/TMM6/TMM10

Arlon

- DiClad Series

- CuClad series

Park-Nelco

- N4000 series

- N5000 series

- N6000 series

- N7000 series

- N8000 series

Getek

- Loss tangent = .012 (slightly high) (usage in analog circuits up to 1.2 ghz and up to 2.0 ghz in digital applications) (Stability in temperature variations good)

- Er = 3.5 to 4.3 (at 1.0 mhz) (specific Er is dependent on glass-resin- ration – Er is virtually constant form 1.0 mhz to 2.0 ghz)

- CTEr = +220ppm per degree C (high). Tg is 180 degrees C.

- Electro-deposited Copper only. (helps in peel strength and delamination but somewhat limits etch width tolerance due to undercutting).

Hybrids

Hybrid circuit boards are created by combining standard FR4 laminate with other RF/microwave/high-speed laminates. This technique gives engineers more control over the design on desired layers while reducing costs by completing the board with standard FR4.